Fine alignment of empty bottles with the "lotus effect"

The innovative water and glue resistant coating on the conveyor belts of the HEUFT empty bottle inspectors ensures full detection reliability and at the same time protects against container jams and line standstills.

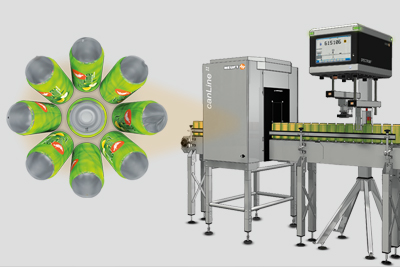

HEUFT InLine II inspectors are equipped with a very special belt drive in order to be able to inspect each single empty bottle on the conveyor all-around from all sides continuously even before the filling process. It rotates the primary packaging to be examined purposefully using servo control so that it is exactly aligned at each individual detection station. The result: a precise sidewall inspection which covers considerably more than 360 degrees of the complete bottle volume. The sensitive conveyor belt is extremely flexible and compressible and also tolerates different container diameters and shapes and adapts itself to these harmonically. On the one hand this reduces the mechanical stress on the drive system and on the other hand makes fast, fully automatic brand changes possible.

It is therefore no surprise that this clever concept sets standards regarding the quality inspection of empty bottles to be filled. Therefore empty container inspectors of the HEUFT InLine II series show their true strength particularly along returnable beverage lines – and find all risks with regard to the appearance, quality and safety of the filled end product in good time from sharp-edged finish chips and glass splinters on the base to defects, inclusions and hairline cracks in the sidewall.

Effective protection against jams, crashes and line standstills

HEUFT has now perfected the in-house developed and self-produced belts for the specific rotation and alignment of empty containers in order to also achieve this in difficult cases: even returning reusable containers which were previously provided with self-adhesive labels can now be transported, aligned and inspected more safely and efficiently than ever before. Besides crashes leading to jams and broken glass can occur in the inspector due to bottles sticking to the belt when such self-adhesive labels have been removed in the washing machine but glue remains are still left on the container body. The new development prevents such problems and therefore the associated line stoppages and productivity losses and protects the inspector itself from damage.

The optimised foam belts remain clean and wear-free in the long term with an unchanged high compressibility. They achieve a service life of up to 4,000 operating hours because they are water-repellent and almost resistant towards the accumulation of glue which in the long run could also impair their suppleness, functionality and durability. In the meantime they have already proved this in several empty bottle inspectors at various large and small beer and soft drink filling companies.