Blow-Fill-Seal case study: Pioneering work at Pioneer

17 February 2026

At the Iraqi company Pioneer Co. for Pharmaceutical Industries, one of the largest blow-fill-seal producers in the Middle East, HEUFT spotter II BFS systems check the product quality, functionality and tightness of infusion bottles and ampoule strips.

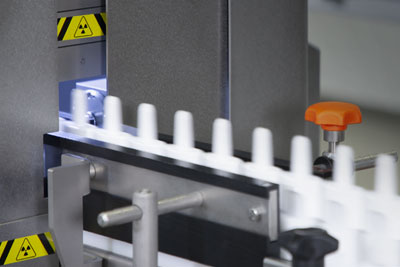

They check the integrity of each individual end product in line. And keep pace even at high line speeds. They do not require a carousel, star wheels, centring tulips or grippers. They contain neither turntables nor container-guiding format parts, which entail high acquisition, maintenance, storage and wear costs and have to be replaced time-consuming when changing products. Their straightforward, space-saving design transports ampoules and polymer infusion bottles filled with parenteral liquids stress-free along different detection stations. This makes them ideally suited to 100% container closure integrity testing (CCIT) of end products manufactured aseptically using blow-fill-seal (BFS) technology.

These are just a few of the reasons why Pioneer Co. for Pharmaceutical Industries decided to install a total of three HEUFT spotter II BFS systems at its plant in Sulaymaniyah, one of the largest cities in the autonomous Iraqi region of Kurdistan. Eleven years after the company was founded in 2010, it had reached its capacity limits when it came to expanding its product portfolio and establishing a secure BFS process in a confined space in addition to the production and packaging of tablets, capsules and syrup.

Complete optical inspection and CCIT

This applies to preparations such as paracetamol, lidocaine and sodium chloride, which are packaged in BFS-Seal infusion bottles with a capacity of up to 500 ml. It also includes water for injection, magnesium sufalt and calcium gluconate, which are packaged in BFS ampoules with a capacity of up to 10 ml. Ten of each are bundled together in a continuous ampoule strip, which, just like the BFS infusion bottles, is manufactured, filled and sealed in a fully automated aseptic process. After sterilisation in an autoclave, they are then transferred by robot from the production line to special inspection and labelling lines. The infusion bottles are labelled there, the ampoules are marked with lot and batch codes using inkjet. And straight-line inspection systems from HEUFT take care of the CCIT.

The installation of the two HEUFT spotter II BFSB devices, which combine high-performance optics with HEUFT squeezer technology to check the integrity and tightness of infusion bottles, was a truly pioneering achievement. Previously, the full packaging had only been subjected to a visual inspection. However, this was not only very labour-intensive, but also time-consuming. Even with 70 employees, it was only possible to carry out random checks on the thousands of products that had to be inspected at once. Minor defects, foreign particles and leaks were not always detected. The HEUFT spotter II BFSB, on the other hand, now inspects every single container thoroughly and also finds such inconspicuous defects.

Gapless ampoule strip inspection with MCIP

The HEUFT spotter II BFSA, which was installed in Sulaymaniyah in the summer of 2023 for the final check of up to 12,000 BFS ampoule strips per hour, also performs a full-covering complete inspection. On the line where they are finally labelled, eleven HEUFT reflexx A.I. cameras scan them from all sides. To ensure that this is always done with full coverage, the compact system has a sophisticated optical mechanism with alternately designed transport belts: on their way through the device, the already filled primary packaging materials are gripped once at the top and once at the bottom.

This ensures full coverage without blind spots at all times. Adaptive lighting methods contribute to the exceptional detection accuracy. Integrated into the intelligent colour sensor cameras, just like the proprietary hardware and software for intelligent image filtering, subtraction and analysis, the in-house developed Multi Colour Image Processing (MCIP) optimally highlights typical characteristics, so that foreign particles inside the container or inclusions, scratches, grooves or black spots in the packaging material can be located much more precisely. For redundancy and greater precision in tightness testing, a high-voltage leakage detection (HVLD) can also be connected to the compact system for BFS ampoule inspection.

Automatic format changeovers, straight-line transport

The innovative MCIP technology is integrated into all three HEUFT systems at Pioneer. This also applies to a fourth device, which will soon be installed there in another BFS line for infusion bottles. Just like the existing ones, this will also be so highly automated that format and programme changes can be carried out quickly and without tools. From the trigger light barriers to cameras and lighting to the transport belts: relevant components do not have to be replaced individually during the changeover. Instead, their respective positions automatically adjust to the changed type. This effectively avoids unnecessarily long downtimes.

Straightforward container transport, including predictive conveyor control, also creates greater efficiency. Millimetre-precise container tracking is ensured from the infeed to the rejection verification. The two systems for inspecting BFS infusion bottles are even equipped with two rejection systems each: a HEUFT mono pushes leaky bottles or those affected by critical defects directly into the waste bin, while the HEUFT DELTA-FW flow diverter transports those with potentially tolerable cosmetic defects to a revision station.

Real turnkey solutions

The conveyor control continuously feeds the devices, ensuring the correct spacing between the individual packaging items. This is because the BFS infusion bottles must not enter the labelling machine too close together. Pioneer had already ordered it before the HEUFT devices and presented the system engineers from Germany with an additional challenge during its integration in Kurdistan. This is because the containers, which are transported upright through the device and via single-lane conveyors to the labelling machine, are labelled there in a horizontal position. To ensure that this is successful, they are carefully turned over using simple mechanical means before they enter the machine.

The first devices installed at Pioneer for integrity testing of BFS infusion bottles have thus become genuine turnkey solutions that combine sophisticated optical complete inspection with proven methods for leakage check, clever belt mechanics and predictive conveyor control. The same applies to the compact system for BFS ampoule inspection, which was added two years later. As the most important BFS filler in the Middle East, the ISO and GMP-certified Pioneer Co. for Pharmaceutical Industries thus achieves exactly what GMP Annex 1 prescribes to ensure the safety and integrity of the sterile-filled primary packaging materials and the microbial purity of their contents: a continuous CCIT of each individual end product.