Preview mineral water industry conference: Valuable exchange of experiences

When the Technical Committee of the Association of German Mineral Water Producers (VDM) meets again in Burgbrohl on November 18, 2025, it will be an important indicator for the leading manufacturer of modular systems for in-line quality inspection in the filling and packaging process. This would not be the first time that the Brunnenfachgespräch (mineral water industry conference) at HEUFT has helped to establish a new state of the art. Holger Kemp, Head of Product Management, reveals this and what else participants can expect there in a preliminary interview.

Do you remember the 52nd Brunnenfachgespräch we hosted here 14 years ago?

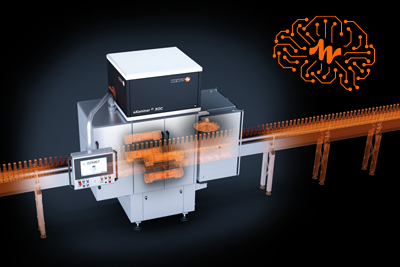

Holger Kemp: "That was before my time at HEUFT. But I do know, of course, that in 2011 we had just launched the world's first empty bottle inspector with pulsed X-ray technology for glass-in-glass detection. Our current HEUFT InLine II IX is already the second successor to this successful model. The feedback we received from the VDM at the time played a part in this success."

Holger Kemp: "That was before my time at HEUFT. But I do know, of course, that in 2011 we had just launched the world's first empty bottle inspector with pulsed X-ray technology for glass-in-glass detection. Our current HEUFT InLine II IX is already the second successor to this successful model. The feedback we received from the VDM at the time played a part in this success."

Really, in what way?

Holger Kemp: "Initially, the concept of combining classic detection methods with our X-ray technology was met with some scepticism. But the 2011 Brunnenfachgespräch showed us that significantly more precise glass splinter detection in empties is really in demand in the industry, especially in the reusable and premium segments. We were already able to demonstrate that it actually works with pulsed X-rays. This encouraged us to stick with this concept and continue to develop it in order to constantly push the boundaries of what can be detected."

And at the upcoming 65th Brunnenfachgespräch, everything here at HEUFT will revolve around the same topic again?

Holger Kemp: "In a way, yes. Combining X-ray and camera detection in one device is and remains state of the art, as there are simply physical limitations to purely optical methods. We will have a lot of new things to show our guests in November. In our view, HEUFT reflexx A.I., the latest version of our own AI for processing and analysing X-ray and camera images, is a real game changer in empty and full bottle inspection. We believe that it will once again shape the state of the art and are eager to see whether the experienced technicians from the VDM see it the same way. In any case, we look forward to receiving feedback, as well as any questions, ideas or suggestions from our guests! Only through this kind of exchange of experience can we work together to achieve the necessary quality, safety, and efficiency in bottling and ensure effective consumer and brand protection now and in the future."

What else can participants expect?

Holger Kemp: "We want to learn first-hand about the challenges facing the industry in terms of quality assurance so that we can continue to deliver the right solutions. As I said, feedback from the VDM is extremely important to us; only together can we shape the future! Our program at the Brunnenfachgespräch offers plenty of opportunity for dialogue. And deep insights into our family business during the factory tour. Current innovations that further advance packaging integrity, product safety and line efficiency will be presented and demonstrated live."