Intelligent empty can inspection: even more options!

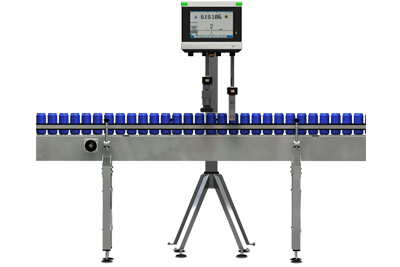

HDRI, deep learning OCV, increased coverage inside and out: the compact HEUFT canLine II now offers significantly more when it comes to the inspection of empty cans at high speed.

Examine up to 144,000 beverage cans per hour already before filling and now also cover areas which were previously considered difficult or impossible to inspect. Dynamically compensate for interfering light reflections and shadows at the same time. Always achieve the necessary image sharpness from the base to the flanged edge at quadrupled resolution. Realise deep learning-capable optical character recognition even with low inkjet coding quality and verify distorted, smudged and blurred best-before dates:

Examine up to 144,000 beverage cans per hour already before filling and now also cover areas which were previously considered difficult or impossible to inspect. Dynamically compensate for interfering light reflections and shadows at the same time. Always achieve the necessary image sharpness from the base to the flanged edge at quadrupled resolution. Realise deep learning-capable optical character recognition even with low inkjet coding quality and verify distorted, smudged and blurred best-before dates:

The intelligent HEUFT reflexx A.I. image processing expands the possibilities of high-speed empty can inspection with the HEUFT canLine II and increases the reliability of detection at the same time.

Full covering internal inspection of each empty can

The compact system can now be equipped with an additional module that completes the gapless inspection of the inside of the can: a HEUFT reflexx A.I. top-down camera generates a total of eight high-resolution views from different perspectives which completely display the sloping inner shoulder area directly below the flanged edge of each individual can all around. The colour sensor camera with adaptive LED lighting and AI-supported image processing developed in-house makes even the smallest damage and contamination such as oil or grease in this sensitive area clearly visible and precisely recognisable.

The compact system can now be equipped with an additional module that completes the gapless inspection of the inside of the can: a HEUFT reflexx A.I. top-down camera generates a total of eight high-resolution views from different perspectives which completely display the sloping inner shoulder area directly below the flanged edge of each individual can all around. The colour sensor camera with adaptive LED lighting and AI-supported image processing developed in-house makes even the smallest damage and contamination such as oil or grease in this sensitive area clearly visible and precisely recognisable.

The new HEUFT reflexx A.I.-Kamera is now also used as standard directly on the HEUFT canLine II control unit for the top-down inspection of the entire interior between the shoulder and the bottom of the can with quadrupled resolution. Detailed High Dynamic Range Images (HDRI) compensate for light reflections and shadows so effectively that even at the highest speeds, not only is the necessary image sharpness ensured throughout, but also a truly homogeneous illumination for gapless and clear vision. In this way, oval-shaped, dented or damaged flanged edges are identified just as reliably as dented or contaminated can walls and dangerous foreign objects at the bottom of the can.

Deep Learning Optical Character Verification

Thanks to significantly more detailed separation and more exact centring of the individual characters as well as deep learning for truly intelligent identification and evaluation of their different appearances, another HEUFT reflexx A.I. camera optionally carries out a reliable bottom-up read of inkjet coding such as best-before dates on the outside of the base of the still unfilled cans. These are sucked up by a particular vacuum conveyor and transported over the encoder and camera. Creeping printing errors and display problems such as misplaced ink dots, distorted, smudged and blurred letters, numbers and lines of text are clearly detected and correctly evaluated by the HEUFT reflexx A.I. image processing system during the optical character verification (OCV) – thanks to the prior teaching-in of a wide range of appearances.

The inspection of the exterior decoration on each individual empty can is another option which the HEUFT canLine II now offers. They are illuminated from above, scanned by a total of four HEUFT reflexx A.I. cameras and compared with a previously taught-in reference image which covers the outer wall of an approved can at 360 degrees in an additional housing in order to ensure that the container colour and design really do match the beverage to be filled in particularly. Reliable identification of non-brand packaging is guaranteed already before filling at line performances of up to 90,000 units per hour. Significantly higher speeds are possible with two modules at the same time.