Tethered cap inspection: HEUFT is ready!

With intensive tests, new software and special lighting, we have prepared our technology for 360° cap inspection for new challenges in the filling process of non-refillable PET bottles. The first devices are already being delivered to major bottlers.

In July 2024, they will become compulsory for bottlers of disposable plastic beverage containers according to EU Directive 2019/904 Single Use Plastics (SUP): tethered caps. From then on, even after opening and consumption, the closures are to remain firmly attached to the primary packaging material in order to counteract the littering of entire landscapes, rivers and oceans with plastic waste.

We want to be prepared for this and have therefore already given our technology for all-round closure inspection an upgrade. Because just like beverage fillers, closure and preform producers or filling and capping machine manufacturers, the new types of lids also pose major challenges for suppliers of inspection systems.

Smart image processing for new types of closures and defects

It is not yet possible to predict what new types of defects will occur in the production, filling and sealing process. And what was clearly a defect in the past will not necessarily be so in the future. The fact that our HEUFT reflexx A.I. image processing always considers unknown objects on the detection images as faults until they have been taught to be good is a clear advantage.

Intensive tests have shown that the proven detection reliability for the optical 360° closure wall inspection of tethered caps with the HEUFT FinalView II CAP is already guaranteed when examining rotationally symmetrical closures as one of their two main types. And in the case of asymmetrical ones the smart image processing makes it possible to specifically evaluate the for instance unusual rotational varying gap between the tamper-evidence and hinge band as good. In this way, it is no longer interpreted as a defect but as typical for the appearance of this new type of closure. Bottles with corresponding closure features are no longer rejected from then on. At full detection accuracy, the false rejection rate remains at the lowest level.

Software upgrade for error-free asymmetrical tethered caps

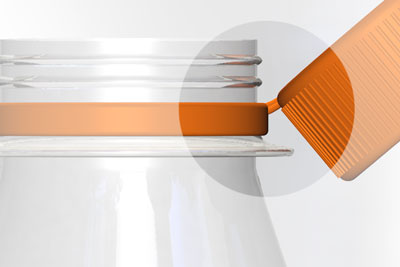

Due to their unusual shape, among other things, asymmetrical tethered caps required a software upgrade for full detection reliability in the tamper-evidence band area. Depending on the orientation of the bottles the four cameras in the HEUFT FinalView II CAP were not always able to image these new caps evenly all round so that important evaluation windows could no longer be centred correctly and aligned to a certain point.

The new software provides a remedy: it rolls out the individual images of the asymmetrical tethered caps to a full 360° view. The masks can then be placed on top of these images in a targeted manner. In this way, the inspection of asymmetrical caps achieves the same precision as is already known from the all-round inspection of rotationally symmetrical bottle caps.

Prepared for rPET, optimised for full closure integrity

In order to be able to meet the requirements of the SUP directive for new minimum proportions of recycled plastic in the years 2025 and 2030, the trend is towards rPET bottles. And these can be less transparent than conventional ones in the mouth and thread area, which also makes it more complex to inspect the tamper-evidence band area of asymmetrical tethered closures, among other things. The HEUFT FinalView II CAP overcomes these new challenges with an upgrade to its illumination hardware.

We have also optimised its closure angle detection as a useful addition to the tried-and-tested overheight control: With tethered caps, too, it is now possible to determine to the exact degree whether they are always aligned at the correct angle to a special marking on the neck or carrying ring of the respective bottle. The results of the 360° closure wall inspection are put into relation with those of the standard integrated top-down camera for colour logo inspection. Together with the specifications of the closure manufacturer, this makes it directly clear whether the new types of closures are correctly and tightly sealed.

Whether symmetrical or asymmetrical: The further developed HEUFT FinalView II CAP is ready in time for the start of the EU-wide tethered cap obligation to inspect these new types of closures precisely all around. The first devices for this purpose are already being delivered to major PET bottlers.