Labelling machine

HEUFT TORNADO II classic

Versatile labeller based on the highly automated HEUFT SPECTRUM II.

The HEUFT TORNADO II classic combines the classic robust design of proven HEUFT labelling machines with the current HEUFT SPECTRUM II platform. This not only increases its automation, performance, precision and operational reliability when applying labels but also makes it much more versatile: up to three different stations for accurate wet glue, self-adhesive and wrap-around labelling can be easily integrated into the new generation labeller. Integrated detection units safeguard the features and quality of the final product sustainably.

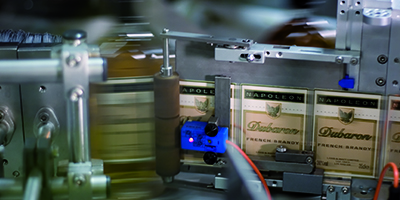

Wet glue labelling

Applying precisely: exacte complete equipment.

Accurate, gentle and tidy: the HEUFT TORNADO II classic can be equipped with up to three coupled wet glue stations for, among other things, body, collar or neck ring labelling depending on the application. The bottles are sent past them after they have been transferred to the carousel and fixed by the centring elements. At the same time the integrated glue segments are covered with an exactly adjustable quantity of glue so that each one of them picks up precisely one label whilst passing.

Read more...

A gripper cylinder then pulls it off and presses it gently with the glued side against the precisely aligned bottle. A sponge ensures a homogeneous application. Labelling platforms rotate the bottles so that the wet glue labels are applied tidily and brushed on without creases. The optionally available automatic magazine feed (see below) ensures that their supply does not run out too quickly and prevents unwanted production stops.

Fullscreen

Wrap-around labelling

Rotating harmoniously: a precise application all around.

A perfect fit, careful and without an offset: special units can be integrated into one or more of the up to three permanently assembled labelling stations of the HEUFT TORNADO II classic easily and flexibly for wrap-around labelling – with individually controllable nozzles which apply fine spots of glue in the right quantity and exactly to the bottles fixed in platforms by means of centring bells. The containers are rotated harmoniously so that the labels can wrap themselves around them completely and precisely – at a speed which can be specifically regulated for different formats.

Read more...

The glue spots which have been applied pull the labels out of the magazine. At the same time a special nozzle applies a thin line of glue to the end of the label for the final gluing so that the overlap can be stuck precisely practically, without an offset, and brushed on carefully. A closed hot glue system keeps glue consumption low and prevents contamination. This reduces maintenance costs and increases operational reliability during the accurate application of wrap-around labels.

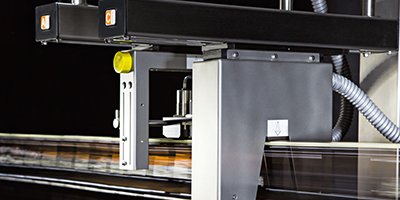

Self-adhesive labelling

Applying accurately: perfectly sticking labelling results.

Dynamic, precise and accurate: corresponding units, with which one or more labelling stations in the HEUFT TORNADO II dynamic can be equipped, apply self-adhesive labels exactly. The bottles enter the labeller if the container stop which stops the production flow in the case of a malfunction is unlocked. The infeed worm ensures that the gap between them is correct in the course of this before they are taken over by the infeed starwheel and transferred to the machine carousel. This is exactly where the self-adhesive labels are applied precisely and with a close fit.

Read more...

The roll with the labels is placed in the labelling unit with servo-controlled dispensing head for this purpose. Thus they can be peeled off at the dispensing plate and applied to the passing bottles using special pads. They are firmly clamped for this – in fact centrally between the rotating platform and the centring bell. Therefore nothing can slip and the labels remain stuck exactly where they belong.

Fullscreen

Label check

More than just labelling: direct presence check.

Double-checking, examining and verifying: the HEUFT TORNADO II classic can do more than "just" apply labels. It also checks the results of its work during the same process. The presence of the labels is checked using sensors. This direct quality assurance can be extended by numerous other checking and inspecting functions upon request (see below).

Fullscreen

Fault rejection

Preventing recalls: the reliable rejection of faulty containers.

Fast, careful and accurate: highest precision when detecting faults is only effective if the products in question are also removed afterwards. The single-segment and multi-segment rejection systems of the HEUFT rejector series deal with this both precisely and carefully.

Fast brand changes

Changing simply: adapting without tools.

Uncomplicated, time-saving and reliable: the HEUFT TORNADO II classic not only keeps time and personnel requirements extremely low during running operation. Brand and program changes are also dealt with fast and easily: no tools whatsoever are required in order to replace the change parts. The vertical adjustment of the labelling units is carried out just as automatically as the correct positioning of the sensors for checking the label presence. This saves human resources and reduces unproductive downtimes to a minimum.

Central lubrification

Greasing automatically: minimum maintenance.

Central, automatic and economical: the correct amount of grease is applied to all the moving parts of the labelling machine so that everything always runs like clockwork. The integrated central lubrication system greases the main bearings and the rotary gears for the bottle platforms and an oil pump the labelling stations. A special labyrinth seal prevents water entering the closed oil system in the course of this. This ensures the durability of all the components sustainably. Complex maintenance work can therefore be dispensed with.

Optional additonal functions

Making even more possible: extensions to the range of functions.

Labelling machines with their modular design based on the HEUFT SPECTRUM II can be expanded at any time. Thus the range of functions of the HEUFT TORNADO II classic can be optionally extended with further functions for optimising and checking the labelling and product quality:

Read more...

-

The rotating cam is no longer controlled mechanically but electronically due to the use of servomotors. This makes it programmable according to the brand so that brand changes can be dealt with fast and easily. In addition this flex technology together with precise camera technology achieves a fine adjustment of the bottles with millimetre accuracy for even more precision when applying labels.

-

The automatic magazine feed (AMF) makes a non-stop labelling operation possible. The servo-controlled add-on module increases the label stock and therefore minimises the need for manual intervention: a new magazine is simply pushed into place during running operation when a magazine is empty. Standstills are therefore sustainably avoided and human resources effectively saved.

-

Camera-based modules check the position, fit, alignment as well as the brand purity of the labels. An intelligent colour sensor camera verifies the best before dates and barcodes which have been applied.

-

Special detection units check the fill height and the internal pressure.

-

The bottle burst detection records burst glass bottles in the infeed, stops the machine and protects it against contamination due to glass splinters.

-

A special collection table prevents the accumulation of containers in the outfeed.

-

Special sensors check the presence and the position of the closures. The logo detection identifies non-brand lids.

-

Special camera technologies carry out a gapless all-around inspection of the closures.

-

The HEUFT sonic checks the tightness of metal lids and crown corks.

-

The clean in place function saves time and supports the employees because it cleans the labelling stations automatically without the time-consuming dismantling of individual components.

-

The innovative hands-off dialog function produces genuinely responsive results during machine analysis and process monitoring and makes the voice control of the HEUFT TORNADO II classic possible.

Fullscreen

HEUFT SPECTRUM II

Simply automating: universal device platform for maximum performance.

Highly automated, universal and powerful: the HEUFT SPECTRUM II ensures optimum detection and operational reliability during an in-line quality assurance for the sustainable safeguarding of product quality and line efficiency.

Read more...

The cross-system control unit with multiprocessing capability for different modules, systems and applications convinces due to its exceptional degree of automation. Brand and format changes can be carried out without manual intervention. The unique human machine interface of the universal device platform is self-explanatory. Human resources are effectively saved in this way. In-house developed hardware and software of the latest generation and a future-proof network connection achieve highest computing power and data transmission in real time. The result: maximum precision during purposeful product tracking, inspection and rejection.

Fullscreen

HEUFT NaVi

Simply knowing what to do: self-explanatory audiovisual user guidance.

Intuitive, individual and audiovisual: previous knowledge is not required in order to operate the HEUFT SPECTRUM II systems reliably. The HEUFT NaVi user guidance is self-explanatory and supports the respective user step by step.

Read more...

An RFID login with user-related access rights provides an overview and makes the respective user's work simply easy: he only sees what he really needs to on the clearly arranged touchscreen user interface with a flat menu structure, integrated tutorials and precise auxiliary tools in order to fulfil his specific tasks optimally. He is supported by a virtual assistant in the course of this. She speaks to him and clearly explains what has to be done when and where. Purposeful and focussed on the essentials – the audiovisual HEUFT NaVi user guidance makes the reliable operation of HEUFT systems simply easy!

Fullscreen

HEUFT checkPoints

Simply seeing where what has to be done: trouble-free localisation.

Clear, direct and purposeful: the user can cope immediately on the rare occasions when manual intervention is needed. Because eye-catching HEUFT checkPoints make it clear at a glance exactly when it is necessary to take matters in hand in addition to the audiovisual information which the HEUFT NaVi provides. The orange tags with clearly assignable letters are on the device components where intervention may be required. If the worst comes to the worst the HEUFT NaVi shows them on the touchscreen. The HEUFT checkPoints then even optionally flash on the respective component in each case. The problem is located without a long search. This saves time and human resources, shortens standstills and therefore increases productivity.

Durable construction

Less maintenance: minimum wear and tear.

Solid, robust and low-maintenance: the HEUFT TORNADO II classic is made of stainless steel and galvanised components. All the moving parts of the low vibration machine are almost non-wearing and therefore very durable. Extremely low maintenance requirements. Thus the rubber parts of the glue segments are vulcanised and dimensionally stable. This ensures the exact positioning of the labels as well as maximum ease of servicing and minimum maintenance requirements. The wear and tear of the specially developed centring heads is also extremely low. The centring bells can be replaced quite simply in one easy movement. All the components which come into contact with the containers are made of plastic. This keeps the noise level during the labelling process to the absolute minimum. The result: a solid, durable and easy to service construction.

HEUFT CleanDesign

Cleaning quite simply: hygiene-optimised construction.

Accessible, clean and safe: its HEUFT CleanDesign predestines the system for use in hygienically sensitive areas.

Read more...

Sloping surfaces facilitate cleaning and prevent the accumulation of stubborn dirt. Special channels and openings allow the liquids required for cleaning purposes to be drained off completely. Consequently dangerous germs and bacteria have no contact surface whatsoever. Specially constructed casings and doors create optimum accessibility. The electronics are totally encapsulated. Sensitive areas such as the inspection units are dust-proof and protected against contact as well as water jets.

Network technologies

Networking everything: online connection for increased efficiency and quality.

Information transmission in real time, production data acquisition, line analysis and remote maintenance: networking is the answer!

Read more...

HEUFT systems have future-proof network interfaces (Gigabit Ethernet and TCP / IP) for an online connection via the Internet and the database interface (SQL / DDE) for top line efficiency and an optimum quality management with considerably faster and easier workflows. Therefore production data, shift records, productivity faults and HACCP limit value analyses are available network-wide. The result: early identification of quality and efficiency problems. The firewall protected direct connection to the HEUFT TeleService makes competent remote maintenance possible all around the clock.

-

versatile labelling machine of the new generation

-

highly automated HEUFT SPECTRUM II platform with audiovisual HEUFT NaVi user guidance

-

high-precision wet-glue, self-adhesive or wrap-around labelling during a single work process

-

integrated detection units for sustainable quality assurance

-

centralised lubrication for the complete machine

-

robust, hard-wearing and durable construction with the hygiene-optimised HEUFT CleanDesign

-

optional hands-off voice control

-

straightforward brand changes and minimum maintenance

-

minimum noise development

-

simple integration into existing lines

-

online connection for remote maintenance and production data acquisition

-

performance range – up to 72,000 containers per hour