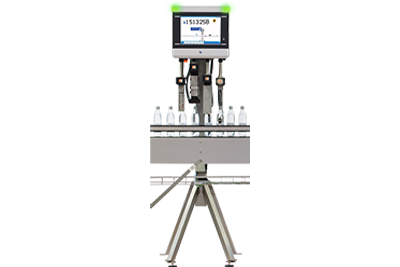

Teachable label inspection

Simply teach-in new labels more quickly: the HEUFT FinalView II LBL shortens downtimes and sustainably increases the availability of entire bottling lines.

Putting new brands into operation takes time. This is particularly true for added bottle labels which only differ in the smallest details from those used up to now – for example when a light variant of a lemonade or an alcohol-free version of an established beer speciality is newly introduced.

For reliable inspection at the end of line, a new label previously had to be evaluated by an expert and manually set as a new variety based on a large number of appropriately equipped bottles. Otherwise, it could happen that tiny deviations in the new label design were interpreted as errors and all affected containers were rejected. What all this means for the availability and productivity of entire bottling lines is anyone's guess. The innovative Teach-in of the HEUFT FinalView II LBL puts an end to this!

Simply easy to teach-in

With the latest expansion stage of our AI-supported HEUFT reflexx A.I. image processing the detection unit for the detailed label inspection significantly accelerates the commissioning of new types – and at the same time simplifies it so that the operator can teach it in himself without any outside help. If the container shape remains unchanged, for example, an appropriately equipped amber glass beer bottle only needs to be inspected once: In less than a minute, the system permanently memorizes the new label with all its characteristic features and design elements.

Even if non-brand labels differ from this template in only a minor detail, affected containers are always recognised and rejected from then on. Putting new types into operation and adapting the optical label inspection to them is now quicker and easier than ever before; downtimes are permanently reduced.

Simply easy to change over

Of course the HEUFT FinalView II LBL detects non-branded, differently coloured and printed labels as well as incorrectly positioned, skewed, wrinkled and torn defective labels. Four high-performance cameras on two levels each generate an undistorted 360° panoramic view of each individual primary packaging material in combination with adaptive LED lighting and intelligent HEUFT reflexx A.I. image processing. Non-critical features such as slight pressure misalignment can be taught in as good objects so that these also no longer lead to rejection.

The height and alignment of the two camera levels adapt to the changed container size just as automatically as the individually controllable LEDs for optimum illumination in each case in order to implement a change of format in a simple and time-saving manner. The HEUFT NaVi user guidance not only offers the user audio-visual step-by-step assistance.

Simply easy to remain productive

Connected to the HEUFT SPECTRUM II VX fill management system the HEUFT FinalView II LBL takes over the fill level check including filler valve monitoring or the closure integrity check among other things in addition to the detailed label inspection with artificial intelligence. And with the latest HEUFT reflexx A.I. version it adapts to new equipment variants as quickly and simply as never before: Putting new label types into operation now only takes a fraction of the time previously required for this. Lengthy, unproductive downtimes are no longer an issue, and the availability of entire bottling lines is noticeably increased.

At the BrauBeviale 2023 in Nuremberg at the end of November, we will show how well this works. See for yourself what is now possible with the HEUFT FinalView II LBL regarding intelligent label inspection: Stand 8-104.