Deep detecting at Anuga FoodTec!

HEUFT reflexx A.I. realizes an X-ray image analysis which goes deeper – and exceeds the limits of visibility when detecting foreign objects. At Anuga FoodTec 2024 in Cologne, we will be taking a deeper look at what deep learning can do for in-line inspection in the food filling and packaging process.

Aluminium in pickles, wire in pasta, stones in red cabbage, metal in metal and glass in glass: dangerous foreign objects such as these are best detected using pulsed X-ray technology, which HEUFT launched over 20 years ago and has been continuously developing ever since. The fact that it achieves full detection reliability with minimal radiation is also thanks to the company's own hardware and software for real-time processing of the X-ray images. It has long been using artificial intelligence (AI) to detect and smartly evaluate a wide variety of objects.

In order to further increase the reliability of foreign body detection and at the same time further reduce the proportion of incorrectly rejected uncontaminated food and packaging materials, a deeper-going AI discipline is now used optionally in X-ray systems from the HEUFT eXaminer II series - namely deep learning: HEUFT reflexx A.I. combines proven image processing methods with a multi-layered neural network which can independently process abstract patterns in a meaningful way. This allows much more to be achieved, especially when analysing X-ray images.

Smart detection using deep learning

That's especially true for loose and disorganized packaged products such as pickles, pasta or red cabbage. But also for unpackaged bulk goods. The latest HEUFT reflexx A.I. version is now able to reliably detect even the smallest high-density foreign bodies in foodstuffs in which this was previously completely impossible – namely in products which appear very inhomogeneous in the X-ray image, with different absorbing structures and cavities between the individual components.

The new deep learning algorithm of the HEUFTreflexx A.I. image processing system therefore distinguishes aluminium fragments in pickles just as smartly from such harmless deviations as ring-shaped wire in ring-shaped noodles or the little stone in a jar of red cabbage. Products that are actually contaminated are simply detected more clearly and productivity losses, packaging and food waste due to unnecessary false rejections are effectively prevented.

Deep insights at Anuga FoodTec 2024

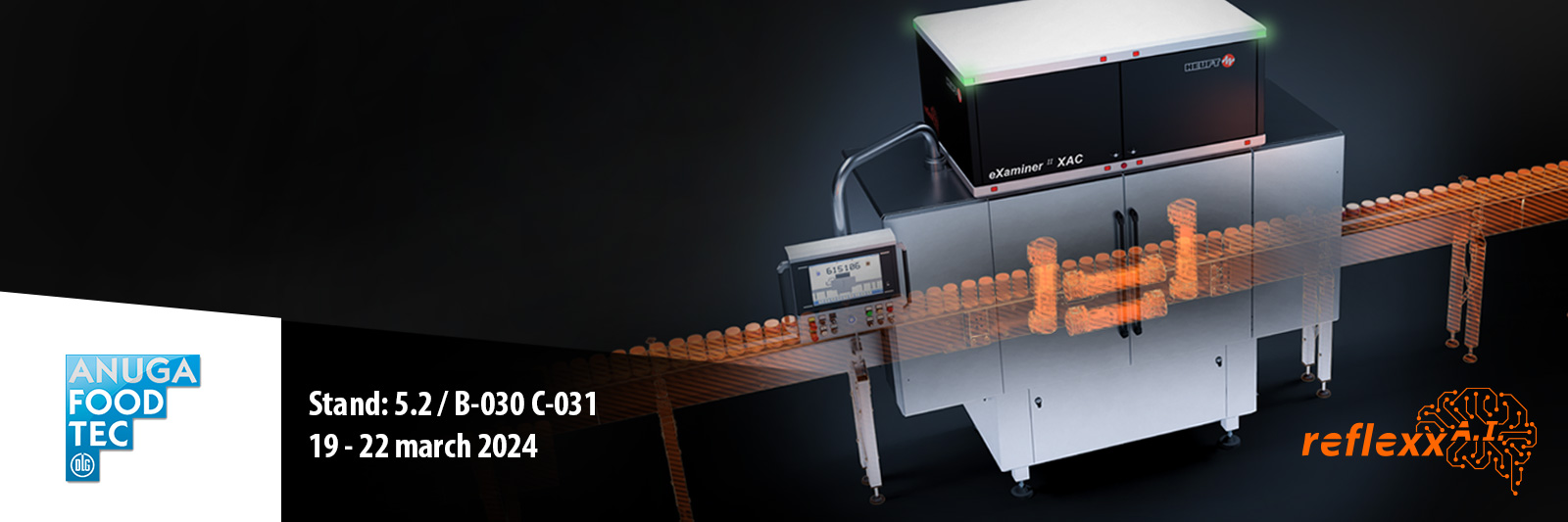

HEUFT will be demonstrating how well this works during pulsed X-ray inspection at Stand B-030 / C-031 in Hall 5.2 at Anuga FoodTec 2024. In addition to the compact HEUFT eXaminer II XS lateral inspector and the HEUFT eXaminer II XT for the inspection of unpackaged product mass in the pipeline, the correspondingly equipped HEUFTeXaminer II XAC which now inspects filled jars and cans in a deeper way, for example, will be one of the highlights at the international supplier trade fair for the food industry from March 19th to 22nd in Cologne.