Absolutely precise: new X-ray fill level detection already tried and tested

A successful test installation at The Absolut Company in Sweden shows that the simultaneous detection of underfills and overfills with the new X-ray measuring bridge from HEUFT also functions just as well in difficult cases with challenging full containers as the camera-based identification of incorrectly applied screw closures.

Identifying both underfilled and overfilled beverage bottles in-line in one and the same work process with only one innovative measuring bridge. Carrying out a precise fill level detection even when the primary packaging is non-transparent or special structures / thickness variations in the glass make the detection difficult. It is easy to maintain that all this is now possible with the new X-ray module from HEUFT. A successful test installation during the daily filling process at Absolut Vodka in Åhus, in the south of Sweden, proves that this actually works where, partly in a two-shift operation, an extremely wide variety of bottles in different shapes, sizes and designs are filled with homemade high-proof alcohol of the highest quality. “We export Absolut Vodka to more than 150 markets around the world”, says Jeffrey Kipping, automation manager of the site.

The spectrum ranges from small 200 millilitre to enormous 1.75 litre bottles in glass which is clear, frosted, embossed, facet-cut, black or even sleeved in all the colours of the rainbow. Consequently an automatic in-line quality check of the Absolut full containers is challenging. A fill level detection in particular is practically impossible with conventional technologies given the varying glass thickness and structures in the critical area around the filling line: empty or extremely underfilled bottles were identified as good again and again and therefore not rejected. An optical examination of the filling quantity inside is not an option simply because the black Absolut 100 bottles are completely opaque just like, for example, the sleeved bottles with their attractive rainbow design. And determining the filling quantity of the special four-sided bottles made of high-quality crystal glass in various thicknesses did not function with any conventional detection unit.

Precise fill level detection even in critical areas

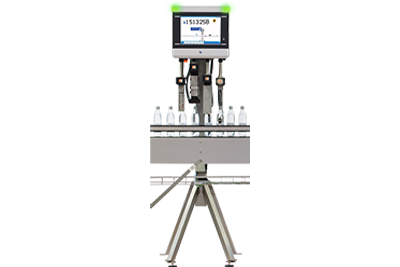

Therefore The Absolut Company (TAC), one of the six brand companies belonging to the globally operating Pernod Ricard Group, needed an X-ray measuring bridge with very special features. And this should be as space-saving as possible so that it could be integrated into existing lines at the Åhus location without any problems. “An integration without any larger disruptions in existing production is crucial”, confirms Jeffrey Kipping. So it was good that HEUFT had just developed a suitable new module for the simultaneous detection of underfilled and overfilled containers in-house which optimally compensates for variations in thickness and special structures in glass. Following a successful online factory acceptance test it was integrated into Line 4 at TAC a good year ago where it was connected to a compact HEUFT SPECTRUM II VX full container inspector for a practical on-site test where up to 20,000 bottles per hour are filled with pure vodka, various mixed vodka drinks and other high-quality spirits.

The results were more than impressive right from the start and still are more than a year later: The smallest deviations in filling quantity are identified reliably and highly precisely even in the critical bottle areas. “Of course any new developed module has its problems when introduced in a real practical environment”, says Mr. Kipping. “But HEUFT responded fast and effective with new firmware and solutions as expected.“

In addition the first HEUFT SPECTRUM II VX installed at Absolut in Åhus offers further valuable functions for a safe fill management and reliable quality inspection of the finished full containers: a locator exposes those filler valves which cause faulty filling in good time and therefore require maintenance, repair or readjustment. And in-house developed sensor cameras with directly integrated image processing detect, for example, incorrectly applied screw closures which are possibly not properly sealed.

Full product quality and full productivity

Furthermore the HEUFT SPECTRUM II VX ensures easy and fast program changes by means of the automatic height adjustment of its measuring bridges with millimetre precision. This not only safeguards the quality of the filled end product sustainably but also maximum line efficiency and productivity at the same time especially in view of the great variety of brands and bottle types which TAC has to offer. And this also applies to particularly challenging primary packaging where a fill level and closure check with conventional methods quickly reaches its limits.

Therefore it is not surprising that after the successful completion of the test installation two more of these full container inspectors, with the innovative X-ray module for the simultaneous detection of underfills and overfills and the smart sensor cameras for an optical closure inspection, will shortly be integrated into filling lines 2 and 6 at TAC as well. This safeguards the full product quality of the Absolut full containers which are exported all over the world. “Quality assurance is important for us through the whole process”, states Automation Engineer Jeffrey Kipping. “And the innovative X-ray module will make it possible to upscale the quality even more.”