Identify underfilling and overfilling even when glass thicknesses fluctuate

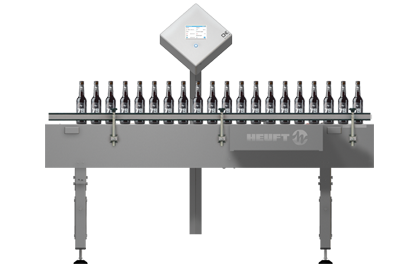

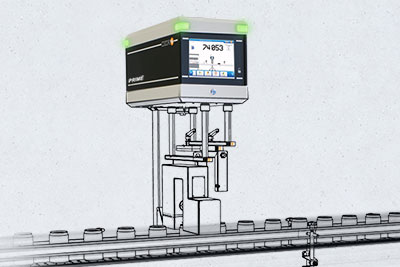

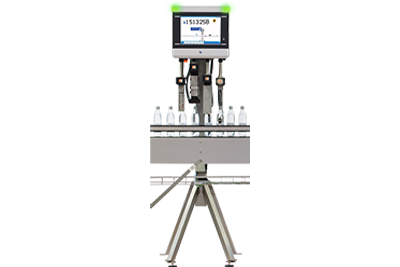

In-house developed, innovative, intelligent: a very special X-ray module provides our full container inspection systems with a significant increase in functionality and detection reliability. With just one and the same measuring bridge the HEUFT ONE , HEUFT PRIME and HEUFT SPECTRUM II VX detect underfilled and overfilled containers at the same time – and even compensate for variations in glass thickness. An exact fill level check is thus realised even in difficult cases.

If there is less in it than is written on it, this may not only be a legal problem, but also really annoying for the customer. After all, he has paid for the full nominal fill quantity indicated on the label! So it's no wonder that he feels he's being taken advantage of and next time he'll choose a competitor's brand. On the other hand, bottlers don't want to deliver an overfull full container either. After all, they don't like to give away any of their valuable product and also want to prevent too much content from causing containers to burst during transport, at the retail outlet or at the end consumer's home. A fill level check that identifies both under- and overfilling of the nominal fill quantity and reliably sorts out the affected primary packaging is therefore highly advisable. Especially if it also ensures that, for example, underfilled bottles are not mistakenly judged to be correctly filled due to deviating glass thickness.

All this now works in a single operation with just one X-ray module which can be connected to the compact HEUFT ONE , the HEUFT PRIME and the HEUFT SPECTRUM II VX filling management system as standard. The newly developed module alone is now sufficient in almost all cases where two measuring bridges were previously necessary in order to detect both underfilled and overfilled bottles, jars and cans: the fill level check covers the area between them completely even if there is a distance of 25 millimeters between the upper and lower fill limit.

Glass thickness fluctuation compensation during fill level check

Thanks to a recent extension of the self-programmed software and the new design of the X-ray receiver, the innovative measuring bridge not only performs one,but up to twelve staggered measurements of the X-ray absorption of each individual packaging material – distributed over the entire height of the filling area to be inspected. Fluctuations in thickness and structures in the container glass, which in conventional one-dimensional measurement absorb X-rays to such an extent that the actual level of the contents could be overlooked, are detected by the additional measurement results and can therefore be specifically compensated for. Thus the inspection of the filling quantity delivers exact results even in difficult cases.

The innovative X-ray measuring bridge for devices such as HEUFT ONE, HEUFT PRIME and HEUFT SPECTRUM II VX also reliably detects underfills and overfills in opaque packaging , metal containers and full goods with special contents such as oils, powders or high-proof alcohol – in other words in special cases where the use of the alternatively available high-frequency level measurement is not always possible