More detection reliability and failure safety during foreign body inspection

HEUFT SYSTEMTECHNIK GMBH will be putting the focus on its further developed technology for the pulsed X-ray inspection of foodstuffs with a reduced total cost of ownership at the Anuga FoodTec 2022 exhibition in Cologne, Stand 5.2 / B030 C031.

Top-down, from the side, from below or from different perspectives at the same time – with one, two or several height-adjustable, flexibly orientable X-ray flashers: what makes the HEUFT eXaminer II series of foreign object detectors so special is not only their versatility for the complete quality inspection of packages filled with food such as thermoformed trays, tins, stand-up pouches or jars.

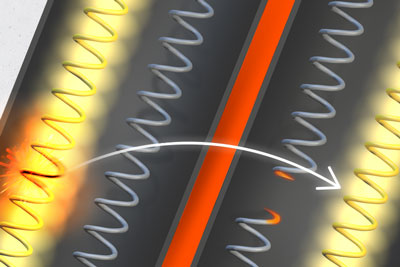

The end-of-line systems of the new generation score points above all with pulsed X-ray technology which now achieves even more sensitivity with a considerably extended lifetime together with smart HEUFT reflexx A.I. image processing. X-ray tubes have been specially developed and other X-ray components have been carefully refined. The turnkey solutions from the HEUFT modular system thus achieve a new level of detection reliability and failure safety for food and packaging which is free of foreign bodies with a further reduction in the total cost of ownership (TCO).

Optimised pulsed X-ray inspection, image processing with artificial intelligence

The X-ray pulses, which are short by the millisecond and are only emitted when there is actually a product to be inspected in front of the respective X-ray flasher, now cover even larger packaging areas and penetrate larger product volumes at the same time. In contrast to conventional continuous beam systems, there is no emission of X-rays either in case of gaps in the production flow or in stop situations. New full-field image converters with a significantly extended lifetime also increase the coverage and sensitivity of the unique pulsed X-ray inspection. In addition to reliable glass-in-glass or metal detection, the targeted identification of weaker absorbing foreign bodies such as bone fragments in pet food or plastic particles in yoghurt pots becomes even more precise with unrivalled low radiation.

In order to clearly distinguish them from harmless product and packaging structures the HEUFT reflexx A.I. combines completely self-developed hardware and software for high-resolution real-time image processing with validatable artificial intelligence (AI) for targeted object detection and classification and a teach-in based on human experience. The user thus always has the option of modifying the AI's judgement and teaching unknown objects, which are initially basically assessed as defects, as good and uncritical for product and packaging safety into a multidimensional feature space, so that only those products are rejected that are actually contaminated with dangerous foreign bodies.

Advanced turnkey solutions for full detection and fail-safe performance

Whether top-down, from the side, from below or from several perspectives at the same time: the modular end-of-line systems of the HEUFT eXaminer II series realise the most varied approaches for a gentle, precise and completely covering X-ray inspection in the smallest of spaces and are based on a common platform with largely identical components. Further detection modules can be integrated in an uncomplicated manner for a 360° closure inspection or marking verification for example. And the extended lifetime of the in-house-developed X-ray components further reduces the TCO and prevents unplanned production interruptions.

The focus will be on the further developed turnkey solutions at Stand 5.2 / B030 C031 from 26th to 29th April at the Anuga FoodTec 2022 in a new type of presentation. The compact HEUFT eXaminer II XB can also be experienced live in operation during the top-down inspection of pet food in thermoformed trays.